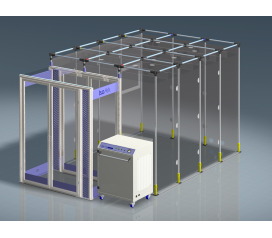

IsoArk 320 Isolation Chamber

The IsoArk 320 portable isolation chamber is designed for rapid deployment of a biologically isolated space from a contaminated environment outside the chamber. The IsoArk 320 system is a comprehensive solution for converting any room or area into a biologically isolated space, providing isolation for infected individuals or materials.

The system meets and completely exceeds current standards for isolation from airborne infections, including the CDC 2003 guidelines for infection control in the hospital environment. Other applications include mail screening, ensuring occupational safety in harmful dusty environments, and performing temporary laboratory work.

The airlock attached to the main chamber allows for movement in and out of the isolation chamber without a drop in negative pressure within the chamber and external contamination. The system can be equipped with additional equipment for treating patients outside the chamber, avoiding contamination of equipment and personnel. It is also possible to place necessary equipment outside the chamber and run probes, wires, and cables through the enclosure into the isolation chamber.

Product Characteristics:

- Proven and effective in healthcare facilities

- Rapid exit through the airlock with a purification system enabling short residence time

- Very simple and quick assembly without tools

- Cost-effective and flexible

- Negative pressure system

- High-efficiency HEPA filter

- Integrated UV radiation source

- Very low noise level

- Transparent chamber

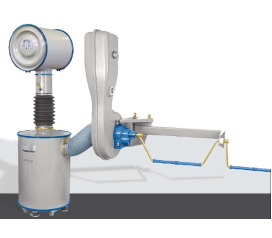

FA 300 HS Filtering System

The integrated FA 300 HS filtering system combines a high-efficiency HEPA filter and a UV radiation source, providing industrial facilities with the highest possible protection against contamination. The system draws contaminated air from the chamber through a pre-filter and a HEPA filter, and exhausts clean air outside. UV radiation built into the filters neutralizes microorganisms trapped on the filter, preventing their accumulation in the system. These features make the FA 300 HS filter a cost-effective and practical solution compared to expensive permanent isolation rooms and provides the necessary protection in seconds.

Main Chamber

The main chamber is made of a lightweight aluminum structure that can be quickly connected, providing support for the transparent chamber cover made of special durable laminate.

Airlock

The airlock is a self-supporting structure consisting of polymeric doors allowing quick and easy access for personnel and equipment. When passing through the airlock, the negative pressure is maintained by double doors. The compact design of the airlock significantly reduces the waiting time for complete air exchange inside and ensures that negative pressure is maintained when leaving and entering the chamber.

Filtering System

The filtering system provides a large airflow allowing for rapid purification while minimizing noise levels and energy consumption when a large amount of energy is not required to purify the air. Additionally, the system is equipped with a differential pressure gauge indicating the condition of the HEPA filter, which does not require tools for replacement.

Technical Specifications

Main Chamber

| Chamber Type | Length (m) | Width (m) | Height (m) | Weight (kg) |

| 90 x 90 | 2.35 | 2.35 | 2.35 | 50 |

| 90 x 120 | 3.10 | 2.35 | 2.35 | 67 |

| 120 x 120 | 3.10 | 3.10 | 2.35 | 89 |

| 120 x 150* | 3.85 | 3.10 | 2.35 | 111 |

Other dimensions available upon request

Airlock (integrated)

| Length (m) | Width (m) | Height (m) | Weight (kg) |

| 0.85 | 0.85 | 2.20 | – |

Filtering System

| Technical Data | FA 300 HS | FA 300 HSA | FA 300 HSB | |||

| Nominal Power | 230 VAC | 115 VAC | 100 VAC | |||

| Energy Consumption | 180 Watt | 200 Watt | 200 Watt | |||

| Nominal Frequency | 50 Hz | 60 Hz | 60 Hz | |||

| Airflow Rate | 300 m3/h | |||||

| Negative Pressure | ≥ 20 Pa | |||||

| Noise Level | 52 dB | |||||

| Filter Efficiency (particle size 0.3μm | 99.9995 % | |||||

| Length (m) | Width (m) | Height (m) | Weight (kg) | |||

| 0.7 | 0.4 | 0.4 | 24 | |||

Transport Bags (included)

| Length (m) | Width (m) | Height (m) | |

| FA 300 HS Filter Transport Bag | 1 | 0.45 | 0.45 |

| Chamber Transport Bag | 1 | 0.70 | 0.20 |

| Frame No. 1 Transport Bag | 2.30 | 0.40 | 0.40 |

| Frame No. 2 Transport Bag | 1 | 0.45 | 0.45 |

Get in touch with our specialist!